CNC machines (both CNC mills and CNC routers) are very useful to makers. With them, you can fabricate custom wood, plastic, or metal parts to the exact dimensions that you define in a CAD (computer-aided design) model. But CNC routers are expensive and CNC mills capable of cutting metal are even pricier—to the point where they are out of the reach of most makers. However, if you have a 3D printer, time, and a modest budget, you can build Ivan Miranda’s CNC mill from scratch.

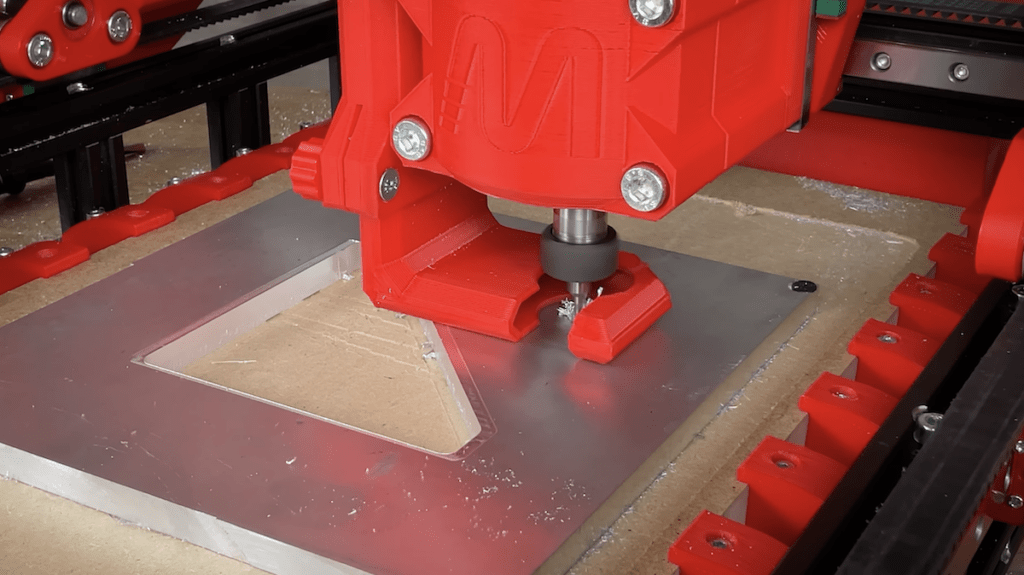

Miranda designed several CNC routers and mills over the years. Like those, this is possible to build using common materials and doesn’t require any special tools except a 3D printer. Its frame is a combination of sturdy, yet affordable, aluminum extrusion and 3D-printed joints. The various hardware, like linear rails, belts, and bearings, is similar to what you would find on a 3D printer. That keeps costs down and makes the parts easy to find.

To control the stepper motors for the machine’s three axes, Miranda’s design calls for an Arduino Uno board paired with a Grbl-compatible CNC shield. It will accept g-code commands from a connected computer via the Serial port and will coordinate the movement of the motors. This mill uses a handheld Makita router for the spindle motor, so there is no need for spindle control provisions.

This machine will easily cut wood and can also handle soft metals, such as aluminum. That capability can do a lot to extend a maker’s fabrication abilities.

The post A 3D-printed CNC mill made from scratch appeared first on Arduino Blog.

No comments:

Post a Comment